- No products in the cart.

Lamp life

Lamps can average 750 hours to 20 000 hours depending on the light source chosen. Average lamp life is the number of hours the lamp should last before it burns out. The average life is determined when 50% of the lamps initially installed are still operating. For lamps with a rated average life of 24 000 hours and more, life is based on survival of 67% of the lamps.

| Lumens per watts | Lamp life (hours) |

|---|---|

| Metal halide (30-112 lumens per watt) | 7 500 - 20 000 hours lamp life |

| Compact fluorescent (62-76 lumens per watt) | 10 000 - 12 000 Hours lamp life |

| Halogen MR16 (50w) (17 lumens per watt) | 4 000 - 5 000 Hours lamp life |

| Incandescent A19 (100w) (15 lumens per watt) | 750 - 1 500 Hours lamp life |

| Linear Fluorescent (31-101 lumens per watt) | 7 500 - 36 000 Hours lamp life |

| Halogen PAR30 (75w) (13 lumens per watt) | 3 000 Hours lamp life |

| Incandescent BR40 (85w) (11 lumens per watt) | 2 500 Hours lamp life |

| LED (50-60 Lumens per watt) | 50 000 - 55 000 hours lamp life |

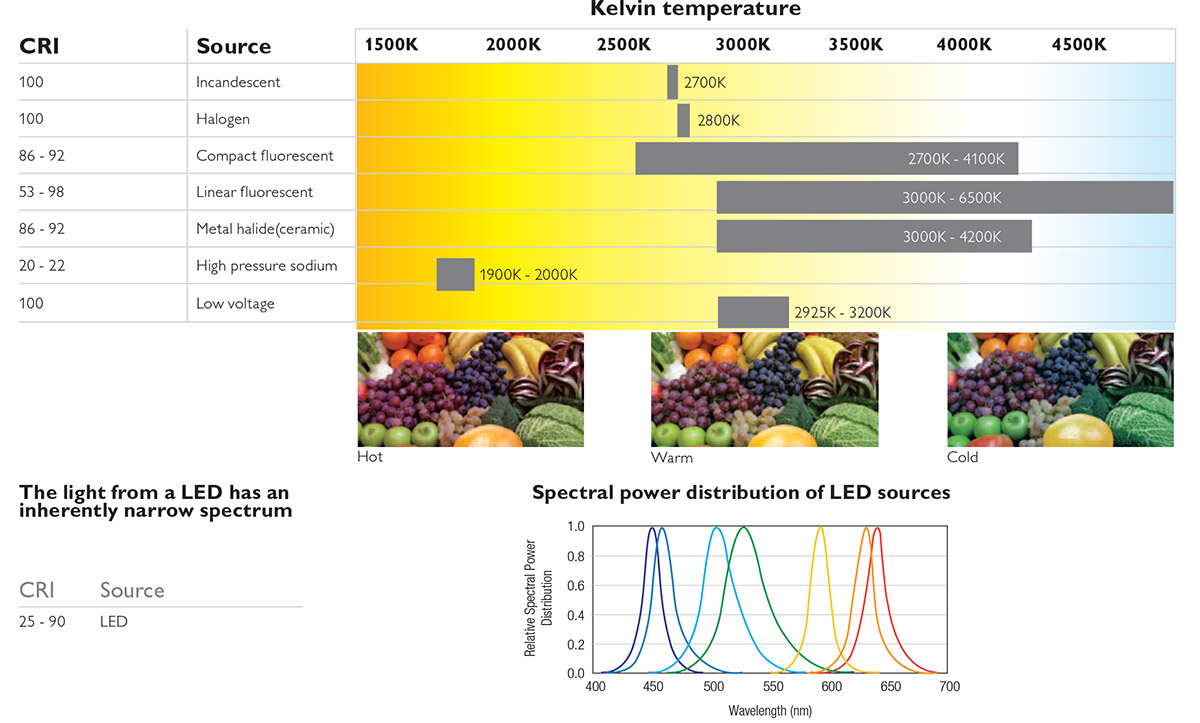

Color rendering index

The color rendering index (CRI) is a relative scale to determine a light source’s ability to render an object’s color. The higher the number, 100 being the best, the better the color rendering. Specify a source that has 90+ where color matching/selection is occurring; 80+ for pleasant appearance of people, food and merchandise; 80+for offices, educational, health care and institutional settings; 70+ for most industrial tasks.

Color temperature

Color temperature is measured in Kelvin and represents whether the light source appears warm (1,500K), neutral (3,500K), cool or daylight (5,500K). The chart below highlights the color temperature and how it affects the mood of the space.

Light source selection and options

Incandescent

The incandescent lamp is a source of electric light that works by incandescence, (a general term for heat-driven light emissions which includes the simple case of black body radiation). An electric current passes through a thin Tungsten filament, heating it until it produces light. A filling gas is often used in the enclosing glass to reduce the filament evaporation rate and improve average life. The enclosing glass bulb prevents the oxygen in air from reaching the hot

The incandescent lamp is a source of electric light that works by incandescence, (a general term for heat-driven light emissions which includes the simple case of black body radiation). An electric current passes through a thin Tungsten filament, heating it until it produces light. A filling gas is often used in the enclosing glass to reduce the filament evaporation rate and improve average life. The enclosing glass bulb prevents the oxygen in air from reaching the hot

filament, which otherwise would be destroyed rapidly by oxidation. Incandescent lamps provide superior color rendering, easy dimming and economical maintenance. The color rendering of incandescent sources ranges all the way from warm tones (approximately 2700K) of conventional A lamps to the brilliant light (approximately 3000K) of tungsten halogen. User should beware that there is pending legislation to ban certain incandescent A shaped light sources. Units featuring reflectorized lamps, such as PAR and low-voltage MR16 lamps, are a good choice for accent lighting and wall washing, or wherever highly controlled beams and long lamp life are desired. The longer life of PAR and low-voltage MR16 lamps also make them a good choice for locations that are difficult to access. Small-scale halogen PAR lamps, such as PAR16 and PAR20, produce crisp, white light that is very similar in effect to low voltage halogen lighting. By

bringing out form, color and texture in the objects being lighted, low voltage halogen lighting draws the viewer in and adds excitement to the composition.

HID

A high-intensity discharge (HID) lamp is a type of electrical lamp which produces light by means of an electric arc between tungsten electrodes housed inside a translucent or transparent fused quartz or fused polycrystalline alumina tube. This tube is filled with both gas and metal salts. The gas facilitates the arc’s initial strike. Once the arc is started, it heats and evaporates the metal salts forming a plasma, which greatly increases the intensity of light

A high-intensity discharge (HID) lamp is a type of electrical lamp which produces light by means of an electric arc between tungsten electrodes housed inside a translucent or transparent fused quartz or fused polycrystalline alumina tube. This tube is filled with both gas and metal salts. The gas facilitates the arc’s initial strike. Once the arc is started, it heats and evaporates the metal salts forming a plasma, which greatly increases the intensity of light

produced by the arc. High-intensity discharge lamps are a type of arc lamp. Compared with fluorescent and incandescent lamps, certain HID lamps have higher luminous efficacy since a greater proportion of their radiation is in visible light as opposed to heat. Their overall luminous efficacy is also much higher, they give a greater amount of light output per watt of electricity input. High Intensity Discharge (HID) light sources provide high output, long life and the greatest possible energy efficiency. These characteristics make them a prime consideration for many commercial applications. Metal Halide is best suited for interior applications as it provides better color rendering than high pressure sodium. HID lighting should be used for ceilings over twelve feet where a strong punch of light is required. For ceilings over 15 feet, consider Metal Halide PAR lamps, which provide an even stronger throw of light.

Fluorescent

A compact fluorescent lamp or fluorescent tube is a gas discharge that uses electricity to excite mercury vapor. The excited mercury atoms produce short-wave ultra violet light that then causes a phosphor to fluoresce, producing visible light. There have been some environmental concerns over the mercury content in fluorescent light sources. Rest assured that due to advancements in technology the levels of mercury content have decreased dramatically (from around 20mg per 4′ lamp to as low as 1.7mg). More and more recycling programs are becoming readily available to safely dispose of the lamps when they reach end of life. Please refer to your lamp manufacturer’s catalog for exact mercury content. Note that the levels may differ between manufacturers.

Unlike incandescent lamps, fluorescent lamps always require a ballast to regulate the lamp power. However, a fluorescent lamp converts electrical power into useful light more efficiently by generating less heat and more light than an incandescent lamp; lower energy costs offsets the higher initial cost of the lamp.

While larger fluorescent lamps have been mostly used in large commercial or institutional buildings, the compact fluorescent lamp is now being used as an energy saving alternative to incandescent lamps in homes. Compared with incandescent lamps, fluorescent lamps use less power for the same amount of light, and generally last longer. While fluorescent is not as easy as incandescent to dim, dedicated electronic fluorescent dimming ballasts are available when required. With excellent improvements in color rendering, color temperature capabilities coupled with state of the art electronic ballasts, fluorescent lamps provide high lumen output with a fast and flicker free start up. In addition, for superior performance capabilities it is recommended to choose a luminaire with excellent performing optics to maximize the element of quality lighting in any application.

While larger fluorescent lamps have been mostly used in large commercial or institutional buildings, the compact fluorescent lamp is now being used as an energy saving alternative to incandescent lamps in homes. Compared with incandescent lamps, fluorescent lamps use less power for the same amount of light, and generally last longer. While fluorescent is not as easy as incandescent to dim, dedicated electronic fluorescent dimming ballasts are available when required. With excellent improvements in color rendering, color temperature capabilities coupled with state of the art electronic ballasts, fluorescent lamps provide high lumen output with a fast and flicker free start up. In addition, for superior performance capabilities it is recommended to choose a luminaire with excellent performing optics to maximize the element of quality lighting in any application.

LED defined

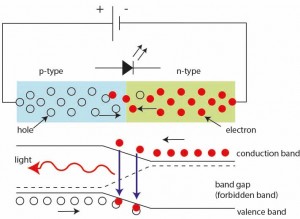

LED is the acronym used for a Light Emitting Diode. LEDs are small semi conductors that allow passage of electrical current in one direction forward from the anode to the cathode. An LED consists of two types of semi conductors P-type and N-type, these two elements need to be placed in direct contact to form a P-N junction.

The difference between LEDs and other diodes is that an LED is designed to produce photons and has a transparent package that allows visible energy (light) to pass through. The color of an LED is determined by the chemical composition of the semiconductor material used in the LED.

Solid state lighting’s evolution

These days, outdoor LED lights are a given. Designers the world over use them to provide a wonderful, glowing illumination for numerous applications. But, like all great technologies, it took years of research and development to get us to the design-friendly space we find ourselves in now. Let’s take a look back and examine the process that made LED lighting what it is today.

The story of LEDs begins in 1962 with a man named Nick Holonyak. Holonyak, seeking to make a name for himself at General Electric (GE) developed the world’s first light emitting diode. Its color? Red. Five years later in ‘67, green LED saw light of day followed by amber in ‘69 and blue in ‘71. Clearly, LED lighting didn’t appear overnight.

Throughout the following decades, numerous uses were discovered for Holonyak’s miraculous new light source including auto indicator lights and traffic lights. But it would not be until 1996 that a great leap forward in LED

would take place with the creation of the first white LED light source. While the quality of this first white light would not allow for interior or exterior design applications, it proved useful for numerous day to day uses including airport markers, exit signs and for use in portable devices like flashlights.

While experimentation with white light LED would continue, so too would the evolution of colored LED lighting. In 1998 RGB luminaires for color changing applications were introduced. These would prove so successful that within five years solid state RGB LED lighting was being used throughout the entertainment industry for theatre, façade and accent applications.

Finally, in 2004, accent lighting appropriate, white LED luminaires were developed but it would still not be until 2008 that LED’s would become an acceptable source of general illumination. The reason? Until that year, designers considered white LED light sources to be too blue as their CRI was quite low. Even today, there are rumblings that LED is too blue for outdoor use with approximately 6000K in CCT.

(Interestingly, some lighting manufacturers recently began a marketing campaign to counter this notion. Their position is that people can see better in blue light.) Even more recently, in an effort to refute these claims, the International Dark-Sky Association (IDA) issued a statement in October 2009 entitled “Blue Light Threatens Animals and People.” The IDA believes that blue tinged light can induce photosynthesis suppression in plants, disrupt the habits of nocturnal animals and upset human sleep patterns and circadian rhythms. Thankfully, in 2010 we are finally seeing the emergence of 4000K color temperature light sources that are much friendlier to our external environments.

So, we have examined LED as a light source, but what about its use in terms of an entire SSL system? (A system comprised of four essential elements – the source, optics, heat dissipation and driver capabilities – that define performance and effective lumen output.) There are many factors to be taken into consideration: LEDs present a high glare and emit light in 180 degrees. They are also small in size. The smaller they are, the easier they are to control, position and direct the optics. Since LEDs don’t like high temperatures, heat dissipation is also crucial; the better the heat sink, the lower the rate of failure. Overall, the final key factor to a well-functioning SSL system is good driver capabilities as the majority of SSL products weigh in at around 50 lumens per watt. Yes, this runs counter to the popular belief that an LED source offers roughly 100 lumens per watt, but when you consider the optic, driver and wiring, all luminaires have their losses. The upside of course is that with SSL lighting systems, lumens can be specifically targeted to the task area, meaning less light wastage compared to HID or fluorescent systems. There are still numerous other advantages to using LED light sources. When dimmed, the lifespan of an LED actually increases. Additionally, LEDs are the only light source that can improve efficacy of electronic transfer into light when dimmed by the actual SSL product itself. So, when you dim an SSL product, your performance actually improves!

When we ask ourselves as designers, “Have we finally arrived at a point where LEDs and SSL lighting products can be safely used for exterior environments?” The answer is a resounding yes. The LED has had and will continue to have a long and productive life.

Solid state lighting (SSL) photometry

In recent years there has been a pivotal shift in the Lighting Industry with the explosion of Light Emitting Diodes (LED) or SSL products. The industry is well informed that this is a rapidly changing technology; however there have been mixed messages and confusion regarding this technology.

Initially we must understand that SSL products are tested by absolute photometry rather than relative photometry which has been applied to conventional light sources. Before delving into how absolute photometry is used to calibrate SSL products it is important to understand the process of relative photometry.

Relative Photometry is generated by first testing the lamp (HID, Fluorescent or Incandescent) then testing the entire “system” (lamp and lighting fixture together) in order to determine its total luminance flux (lumen output). Lamp testing is conducted under precise conditions. For further explanation on lamp testing procedures, please refer to IES LM 54 1999. Our concern is not how the lamp is tested but how the entire system is calculated. Once the lamp data and published lumen output are obtained, this can be divided to determine Lamp Factor. The Lamp Factor is then applied to all luminous intensity values (candela) to stabilize the “system”. This results in an electronic report which generates a photometric report. (Refer. IES Standard LM- 63).

The candela value from the lamp manufacturers is the basis contained in the report. For further information please refer to IES LM-46-04.

You may ask how SSL differs. Rather than testing a light source

and then the system, SSL lighting is tested as a complete system.

There are no variables or changes when it comes to solid state light

products. SSL performance is dependant on the optics employed,

thermal properties and driver capabilities in order to generate

accurate photometric data to create an absolute photometric file.

These reports are unconditional data. The results are absolute. To

provide further clarification, a few facts need to be stated regarding

this method of testing;

• This method cannot accurately scale for different SSL sources.

• Often ten SSL products will be tested all with different outcomes.

It is important to ensure the manufacturer is publishing data in

the bottom 30% of averages (any reputable manufacturer should

publish in this range) to attain the desired performance once the

product is installed. If the manufacturer is publishing the best of

ten, there is a risk of disappointment and a lacking in light levels

upon installation.

• An indication that the photometric data has been performed using

the absolute method is a (-1) in the lumen output space.

• For further information please refer to IES LM 79-08.